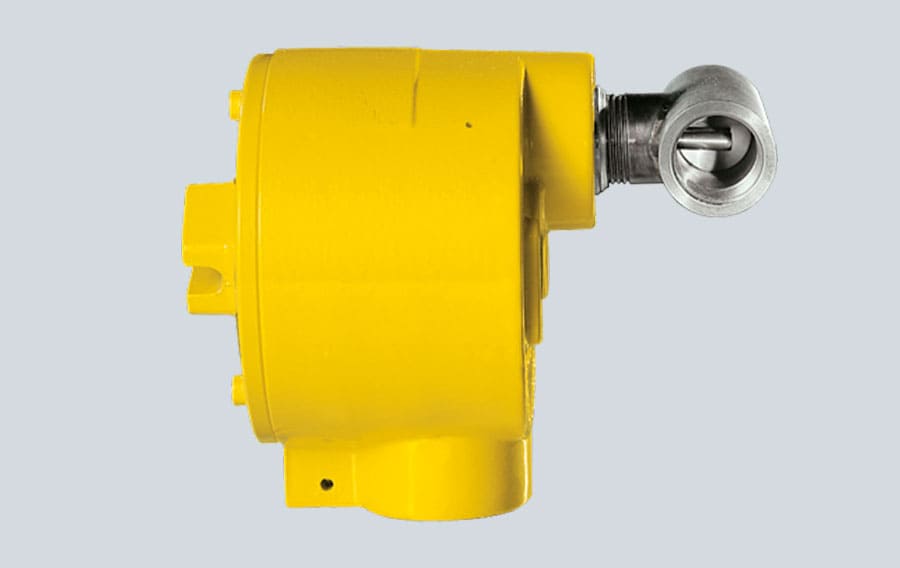

FCI FLT 93S Flow switch (pump protection)

Flow switches or liquids and gases provide a signal if the flow rate exceeds or falls below a setpoint value (e.g. for pump protection). FCI flow switches use thermal dispersion measurement technology. Two pins (thermo elements) are immersed in the medium to be measured. One pin, the active temperature sensor (PT1000) is heated, the other PT1000 measures the temperature. The passing medium causes a cooling effect, which is measured as a temperature difference (Delta T) and calculated in the device. This measuring system does not require a measuring computer or additional sensors. A single process connection is sufficient. Due to their design, the sensors are extremely robust and durable.

Technical data:

Further information can be found at:

+41 (0) 61 378 96 00

inrag@inrag.ch

fluidcomponents.com / flt93s-flow-switch

FCI FLT 93L Inline flow switch (pump protection)

Flow switches for liquids and gases provide a signal if the flow rate exceeds or falls below a setpoint value (e.g. for pump protection). FCI flow switches use thermal dispersion measurement technology. Two pins (thermo elements) are immersed in the medium to be measured. One pin, the active temperature sensor (PT1000) is heated, the other PT1000 measures the temperature. The passing medium causes a cooling effect, which is measured as a temperature difference (Delta T) and calculated in the device. This measuring system does not require a measuring computer or additional sensors. A single process connection is sufficient. Due to their design, the sensors are extremely robust and durable.

Technical data:

Further information can be found at:

+41 (0) 61 378 96 00

inrag@inrag.ch

fluidcomponents.com / flt93l-flow-switch

FCI FS10A / FS10i flow switch + monitor

Flow switch + monitor or process monitoring (also pharma / food ...). Suitable for very small flow rates such as leak monitoring. The measuring principle is the thermal dispersion measuring technique see FLT93S. This measuring system does not require a measuring computer or additional sensors. A single process connection is sufficient. In addition to the switch output, the FS10 devices have a 4-20 mA trend output.

FS10A – Inline process connection 1/4 inch and 1/2 inch NPT thread

FS10i – Screw-in process connection 1/4 inch and 1/2 inch NPT thread

Technical data:

Further information can be found at:

+41 (0) 61 378 96 00

inrag@inrag.ch

fluidcomponents.com / fs10a-analyzer-flow-switch-monitor

fluidcomponents.com / fs10i-flow-switch-monitor